You may have seen a circuit board in your electronic appliance and device and wondered what it is. Circuit boards house the most crucial parts of our electronics, including circuitry.

But that’s not all. They are an integral part without which most devices and appliances won’t function. For instance, your computer will not work if it doesn’t have it.

So is it robust because it is essential? No, they are delicate and need a lot of care to last.

Suppose you need the information to make and prolong the lifetime of your circuit board; worry not. In today’s piece, we’ll look at what circuit boards are and more.

Table of Contents

- What’s A Circuit Board

- Improving Circuit Board Layout Efficiency

- Causes of Circuit Board Failures

- How To Repair Circuit Boards

- Considerations Before Choosing A Circuit Board Manufacturer

- Circuit Board Applications

- FAQs

- Final Remarks

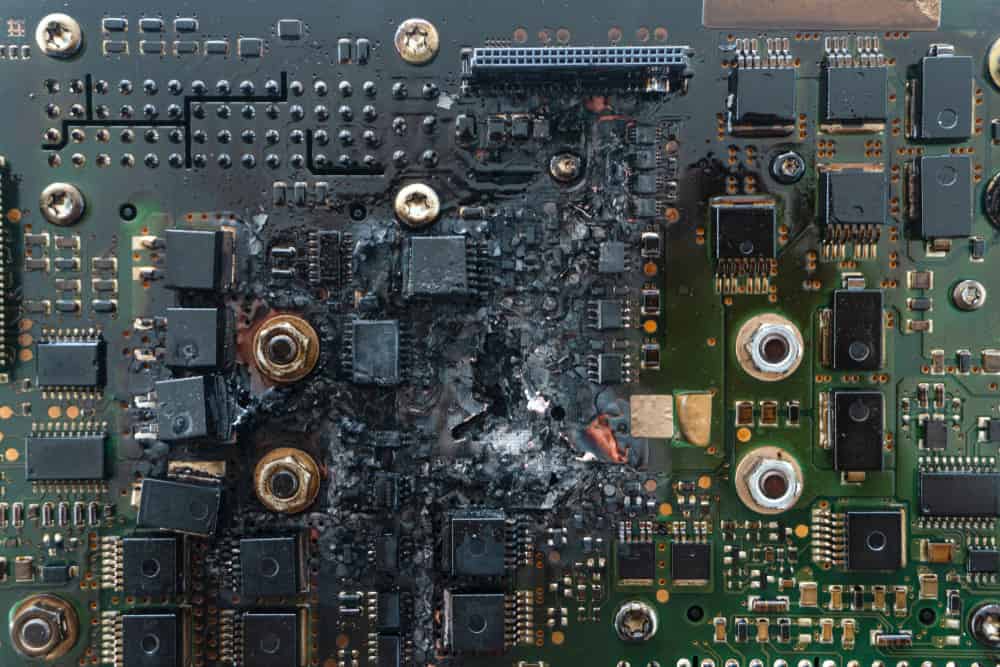

What’s A Circuit Board

(A hand holding a PCB)

A circuit board is a PCB with metal traces and parts for mounting components like the CPU and resistors.

The metal traces are a substitute for the wire connectors used in the earlier days before the invention of the circuit board.

Additionally, they allow electricity to flow between components to power up your device.

Improving Circuit Board Layout Efficiency

(Designing a PCB using CAD software)

Small changes can determine whether your circuit board will last long or not. In this section, we’re looking at industry-recommended ways that you can tweak your circuit board design to improve efficiency:

First, use a do-it-yourself (DIY) approach to create the schematic. Doing so lets you know the critical circuit parts’ exact design and placement.

Next, space the components while avoiding placing traces at right angles. We recommend adopting a 45° angle to avoid overcrowding the board.

Also, place components while adhering to a uniform orientation to make soldering them easier. Fourth, determine the best line width to ensure sufficient current flows.

Fifth, create a ground plane to ensure constant current flows throughout your circuit. Lastly, add heat sinks to potential heat spots within the circuit.

Failure to do so will lead to overheating, which may damage the board.

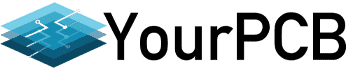

Causes of Circuit Board Failures

(A PCB with damage from electrical short circuits)

If you’re using a computer, you may notice it getting slower with age. Mainly, manufacturers will indicate the length of time that one can use a device before it starts developing issues.

However, some people use devices for periods well above what the manufacturer expects. So, here, we’re giving you the most common reasons for circuit board failures.

Environmental Factors

Any weather elements affecting electrical circuits will cause your circuit board to fail. Generally, exposing uninsulated electrical components to rain will lead to deterioration.

Therefore, the same applies to circuit boards, as they are prone to failure due to corrosion and short circuit.

Electrical Overload

If you look at your power cable, you will notice they have an adapter. In other cases, you’ll notice that the socket has some form of a fuse.

Fuses cut out power to the device in the case of an overload. And an overload is a situation whereby a voltage spike occurs, causing the power cable to pass excess power to your circuit board.

Consequently, it will damage your board or cause some components to fail.

Physical Damage

Circuit boards are delicate electrical pieces that have little tolerance to physical stress. Therefore, any force that bends the board will cause it to fail as it breaks its circuitry.

Moreover, any physical stress that damages critical components, such as the CPU, will damage it.

Electromagnetic Interference (EMI)

Keeping your circuit board close to a source that generates massive EMI will interrupt its signals and communication. Furthermore, it may disrupt the power supply causing some components to malfunction.

How To Repair Circuit Boards

(A man repairing a circuit board)

Repairing printed circuit boards is easy, especially if you know what you’re doing:

First, you’ll need to assemble all the tools and materials needed to commence your PCB’s repair.

Second, remove any damaged component using a sharp knife or flathead screwdriver. Third, use a cloth with rubbing alcohol to clean the tracks.

Fourth, connect your new component well with copper tape over the track. Fifth, place your component and solder it with the appropriate equipment.

Lastly, use a craft knife to cut out the excess tape from your circuit board.

Considerations Before Choosing A Circuit Board Manufacturer

We have thousands of circuit board manufacturers all over the globe. Each promises to satisfy your circuit board needs, but we all know that isn’t true.

Therefore, we’re giving you some factors you need to consider before settling on a circuit board manufacturer.

Industry Expertise and Capabilities

Look at a manufacturer’s industry expertise to determine if they have what it takes to ensure you get a high-quality board.

Additionally, look at their capabilities to determine if they have the right equipment to deliver as per your requests.

From experience, the best way to find out is by looking at customer reviews. Thus, avoid a manufacturer that has a lot of negative reviews.

Certifications

Circuit board manufacturing adheres to laid-out industrial requirements for PCBs. At the very least, consider if the manufacturer has a Quality Management System (QMS) such as the ISO 9001 certification.

Professionalism

Consider the delivery time and whether the manufacturer adheres to your needs. Furthermore, they have to deliver every stage of your project on time.

If not, they should inform you without trying to cover up certain things.

Circuit Board Applications

(Robots rely on printed circuit boards)

Common circuit board applications include:

- Consumer electronics

- Automotive systems like engine management and infotainment systems

- Medical devices

- Also, the aerospace industry, like navigation systems

- Industrial control and robotics

- Wind turbines and energy storage systems

- Home automation

- Lastly, wearable devices

FAQs

How many circuit board types do we have?

Circuit boards exist many, as the number depends on the application. For example, you may find some circuit boards in certain systems and not others.

Additionally, the device you’re using determines your circuit board. Here are some circuit boards that we have:

High-frequency PCB: This type of PCB operates at high frequencies. Moreover, we use it in applications such as wireless communication and radar systems.

High-density PCB: This type packs many components into a small space. So, engineers use it in applications such as computer motherboards and mobile devices.

Flexible PCB: It’s made from a flexible material like plastic or polyimide. As such, you can bend or twist it to fit into tight spaces.

Single-sided PCB: Engineers design single-sided PCBs with components on only one side of the board. Moreover, the other side will have copper traces.

Double-sided PCB: The PCBs have components and copper traces on both sides. Afterward, engineers connect both sides by vias.

Multilayer PCB: It has many layers of copper traces and components separated by insulating material.

What’s the difference between a circuit board and a motherboard?

A circuit board is a general term referring to an electronic board with electronic components and connections. On the other hand, a motherboard is a circuit board for electronic components.

For example, the circuit board in your computer or mobile device is a motherboard.

Engineers design it to include vital features such as expansion slots, CPUs, and power management circuitry.

Additionally, we use circuit boards in many applications that need an electronic circuit. They vary in size and complexity depending on the application.

What benefits do circuit boards offer?

Circuit boards have many benefits to us human beings. No wonder we use them in thousands of applications and devices around the globe. Some of these benefits include:

First, circuit boards reduce the size of our devices. They pack complex circuits into small spaces that allow for the miniaturization of a system.

Second, circuit boards reduce the cost of production of electronic devices and electrical systems. You can imagine how long it would take to wire up a computer if it didn’t have a circuit board.

Thirdly, circuit boards allow you to customize and optimize an electrical system.

They do it because they’re versatile, and you can change certain steps during design to allow it for use in multiple applications.

Fourth, circuit boards are simpler than using wires to connect your circuits. Case example, they have slots where you can insert peripherals.

When you want to repair an item, all you do is remove the peripherals, and you can access the board.

What’s the Durability of Circuit Boards

Circuit boards are durable and may last you for longer than you expect. However, their durability relies heavily on how you maintain them.

Additionally, you’ll need to ensure that all components work well for durability. Case example, powering a computer without a fan will damage it due to overheating.

Moreover, the materials you’re using to design your circuit board will determine how long it will last.

If you design one using substandard materials, be sure that it will degrade faster than one made of high-quality materials.

Final Remarks

If you have an electronic device, it is likely to have a circuit board. Most appliances in our homes and professional spaces have different circuit boards.

Therefore, knowing the important things about them will go a long way to helping you.

Luckily, we’ve detailed some vital information to help you understand these important items in our lives.