About Box Build Assembly, We all understand how complex PCB manufacturing is. Things become worse when you want to manufacture products at production volume.

This is where aspects like embedded firmware and cabling come into question. Fortunately, technology has given birth to box-build assembly, enabling the production of quality electronics seamlessly.

Generally, this efficient approach delivers products in a usable enclosure with wires and power.

But is box-build assembly beneficial? And how can you go about the process? Keep reading to find out.

Table of Contents

- What Is A Box Build Assembly?

- Considerations in Box Build Assemblies

- Benefits of Good Box Build Assembly Services

- The Process of Box Build Assembly

- Applications of PCB Box Build

- FAQ

- Conclusion

What Is A Box Build Assembly?

This is the process of assembling different PCBs connected through several wiring. In other words, it involves all electronic design and manufacturing assembly processes on top of PCB production.

Surprisingly, it starts from PCB fabrication to installation and component connection to form a complete system.

Moreover, we link the PCBs and components using cables and wires. Ultimately, we’ll have a PCBA in an enclosure where it’s packaged.

Some of the components you’ll find in a box build assembly include:

- An enclosure

- Batteries to provide power

- Cables and wiring

- Heat sink attachments having thermal interface materials

- Connectors, including modular connectors

- Additional PCB attachments like standoffs and brackets

- Additional PCB attachments like fans

Considerations in Box Build Assemblies

If you plan on trying out the box build assembly process, consider the following factors:

Bill of Materials

(A bill of material)

The bill of material doesn’t top our list by accident. Generally, every EMS provider should have this factor in their mind. This is the time to understand the key components of your device.

The aim is to determine what you already have and can source. Surprisingly, you’ll even access some components for free.

Find time to define every component focusing more on the small ones like heat sinks. This will help you eliminate delays and unnecessary expenses during manufacturing.

Assembly

Your only task will be selecting the best assembler or manufacturer. Surprisingly, the manufacturer will handle everything from start to end. However, a good manufacturer should avail 3D CAD models.

We guarantee you that you’ll have access to good CAD packages thanks to the variety available.

The manufacturer must identify power sources, mounting options, and environmental challenges. Moreover, good manufacturers consider additional requirements like security needs.

Sample Unit

Consider having a reliable sample unit to provide data when the drawings are incomplete. Even after getting the data for the incomplete drawing, you need a provider to finish the drawing.

Dimensions

Consider having clear details for the unit’s weight and size. This helps with your device’s shipping and handling. Also, take into account the item’s packaging.

Testing

(An engineer testing components)

This consideration applies more to electrical systems. Here, it would be best if you defined basic electrical safety testing like flash tests and earth bonds.

Also, consider whether or not you wish to do factory acceptance or functional testing before the product gets to the customer. We recommend seeking advice from an EMC provider for the best approach.

Benefits of Good Box Build Assembly Services

(Services icon)

Faster Turnaround

We know of many electronic manufacturing services that can quickly develop a working prototype from your 3D CAD model.

Surprisingly, they achieve all these using off-the-shelf components. All they’ll ask for is a blueprint and a bill of materials.

Reduces Manufacturing Costs

You’ll greatly incur a lower per-item cost if you outsource the design and manufacturing of a box-build assembly from reliable electronic manufacturing services.

Interestingly, EMS uses economies of scale to pay less for connectors, wires, and other components.

Moreover, they have experienced technical staff that takes little time and resources to test and install many build boxes. Generally, they offer more high-quality products than if you do everything yourself.

Furthermore, competent employees can also help you easily switch between models. Therefore, changing or developing a custom design will cost you less.

Better Quality

A good box-build assembly service presents the following benefits:

- First, they understand every component they add to your build box

- Secondly, they have more experience working with building boxes and assembly components like wires, connectors, and enclosures.

- Thirdly, they understand how to test box-build components and, where necessary, make reliable repairs.

- Finally, they know how to integrate the systems to guarantee higher assembly processes.

Generally, a good box-build assembly service guarantees a high-quality product.

It Simplifies The Supply Chain

Most electronic manufacturing services, including purchasing components like cables or PCBs, will take over everything.

Surprisingly, some EMS even hold subassemblies until you can integrate them. Consequently, the whole supply chain process becomes straightforward.

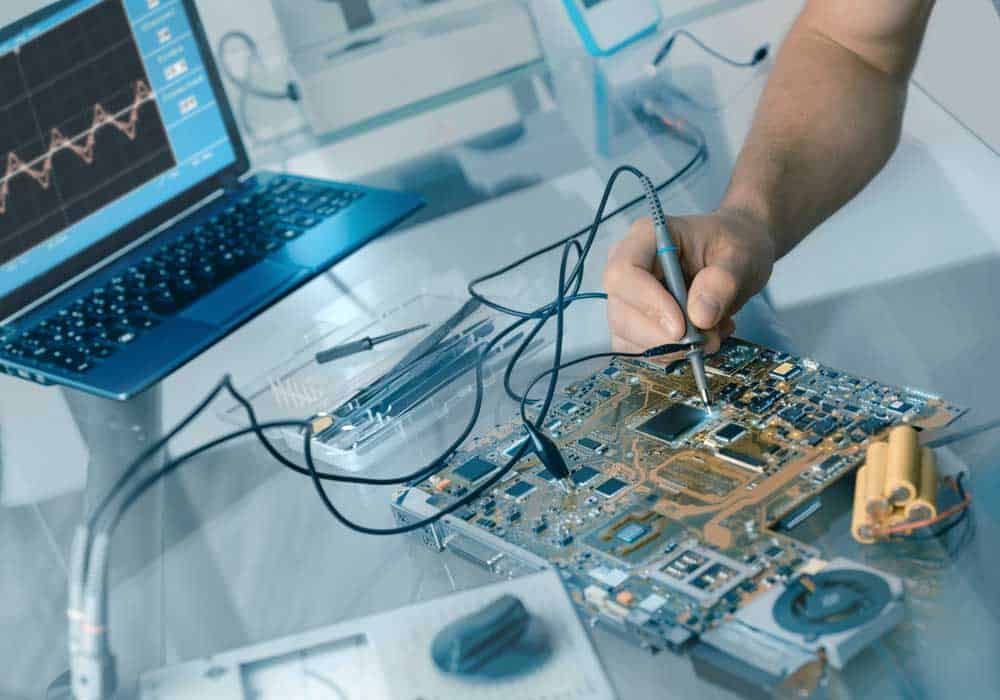

The Process of Box Build Assembly

Even though box builds vary depending on the type and complexity of components you use, the assembly process is more or less the same. Check the steps below:

- The first step involves project preparation. Here, you need to supply your box-build manufacturer with relevant documentation like schematics, bills of material, design files, and testing data. Surprisingly, the assembly process will experience fewer errors and quality output if the manufacturer accesses all the documentation.

- Next, you test the components and sub-assemblies to ensure they meet the specifications.

- You can prepare your wires and cables. This involves cutting, crimping, labeling, and striping cables.

- At this point, your chosen manufacturer installs and connects the components and cables in the box.

- The manufacturer labels the components for easier identification. Moreover, they test or inspect the box build assembly at selected intervals.

- Finally, a software installation takes place. Most electronic assemblies function on specific software. The manufacturer should test the software to ensure it works well.

Applications of PCB Box Build

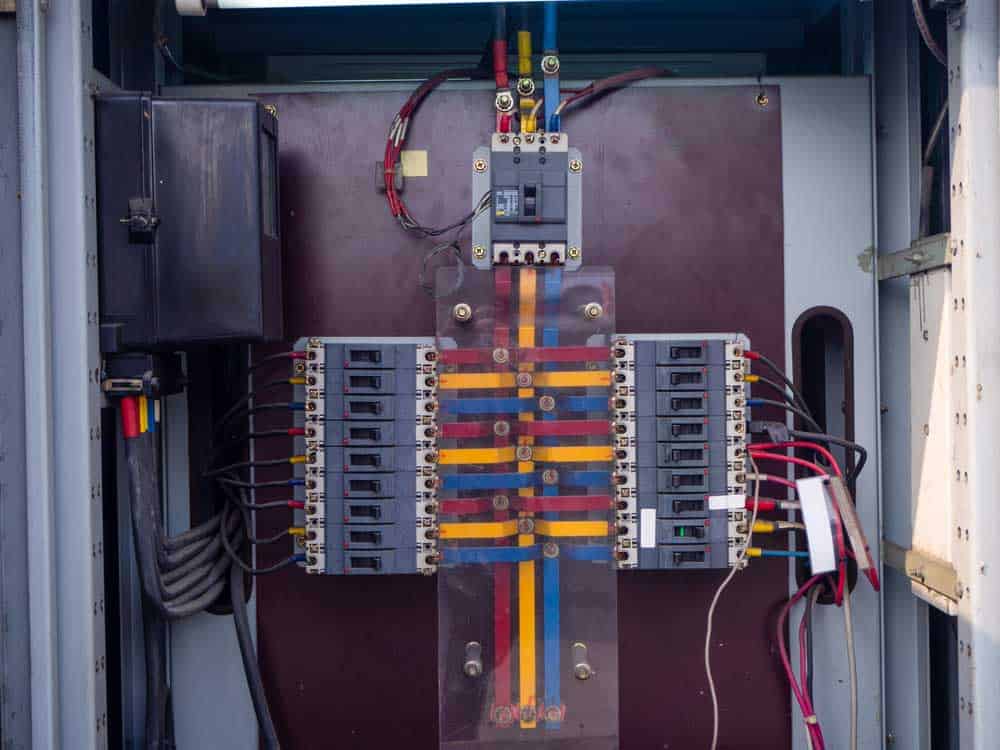

(electrical panel assembly)

Contrary to expectations, box-build assembly finds applications in many areas. You’ll find them in use in power and control circuits. Surprisingly, these devices are more used in things that need covering from physical damage.

We also realized that the application of these services is always changing, making it difficult to plan for its physical design.

FAQ

What will box builder assembly services offer you?

Some of the services you’ll get include:

- Labeling the box build components

- Software and product configuration

- Product-level assembly and software installation

- Design and engineering

- System-level and sub-level assembly

- Box build system testing

- Repair services

- Packaging, shipping, and warehousing

How many types of box-build assemblies are there?

We have simple and complex box-build assemblies. Surprisingly, both options will take you through certain processes.

Conclusion

Box build assembly is increasingly being used throughout the globe, particularly in the aerospace, satellite, and telecommunications sectors.

Surprisingly, they serve as the foundation for the majority of technology. Additionally, they change based on the application and industry in the issue.

As stated, hiring a reputable box to construct assembly service provider will enable you to complete projects more quickly, with higher quality, and for less money.

Additionally, remember the elements we highlighted above for a successful assembly procedure.