What is an assembly drawing, and what are the different types? We are sure you’re here for urgent answers to these critical questions.

Generally, assembly drawings are drawings we use to show a system and its accompanying component’s identity. Therefore, it shows the component’s standard requirements and assembly sequence labeling.

Moreover, the drawings show sections, weight, orthogonal plans, and bills of materials.

But are assembly drawings really important? And how different are they from detailed drawings? For answers to such questions, keep reading.

Table of Contents

- What’s Assembly Drawing?

- Types of Assembly Drawings

- Importance of Assembly Drawings

- What is The Difference Between Assembly and Detail drawing?

- FAQ

- Conclusion

What’s Assembly Drawing?

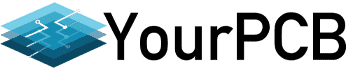

(A ball-bearing drawing)

This drawing displays your machine or its parts and the accompanying components.

Surprisingly, these drawings will show you the sections, weight, mass, elevations, bill of materials, and orthogonal planes. Therefore, as a technical person, you can use assembly drawing to convey your ideas to your colleague.

Moreover, we design these drawings for devices, products, and machinery. Finally, for the drawings to be reliable, they need to comply with the following requirements:

- Manufacturing requirements

- Maintenance requirements

- Operational requirements.

Types of Assembly Drawings

(An engineer checking an assembly drawing)

Check out the different types of assembly drawings below:

General Assembly Drawings

These drawings identify the different components and their working relationships.

Interestingly, it has a detailed drawing of the components and the subassembly and informs you how to make the final assembly.

We can divide the general assembly drawings into four categories below:

Design Drawings

We all know what a design is and what it’s used for. Well, what we use to represent systems or circuits during the design stage is what we call design drawings.

Surprisingly, these drawings display the whole circuit detailing the components you must use.

You should be able to visualize the circuit performance from a design drawing. However, understanding design drawings might be only limited to experts.

Detailed Drawings

A detailed drawing gives you almost everything you need to assemble a machine.

Surprisingly, you’ll access critical information like materials and joining techniques.

Moreover, the drawings provide the dimension of the specific components. However, we recommend these drawings for smaller machines.

Assembly Drawings for Catalogs

These drawings help companies to show their potential customers their product designs. The drawings should be of the highest standard and contain all important details.

Assembly drawings for Instruction Manuals

To begin with, almost every product you buy will come with an instruction manual. Therefore, these drawings operate the same as normal instruction manuals.

They can help you dismantle your device to check the parts.

However, while dismantling the device, ensure you label every component. It might help you while reassembling the parts.

Installation Drawings

These drawings are in place to help you assemble a machine. Generally, it explains how you position components about adjacent or supporting components.

Moreover, it gives you information about general configuration, hardware description, and dimensional data.

Therefore, installation drawings should give machine assembling instructions since they reveal all machine parts in their correct working position.

Exploded Assembly Drawing

This represents an object’s technical drawing showing the different components. Sometimes, you’ll see the slightly suspended components in surrounding spaces in certain assembly sequences.

Therefore, you’ll clearly understand how the final product fits together.

Surprisingly, exploded assembly drawings are simple to understand. Therefore, you can use them in manuals, instruction materials, assembly, or parts catalogs.

Schematic Assembly Drawing

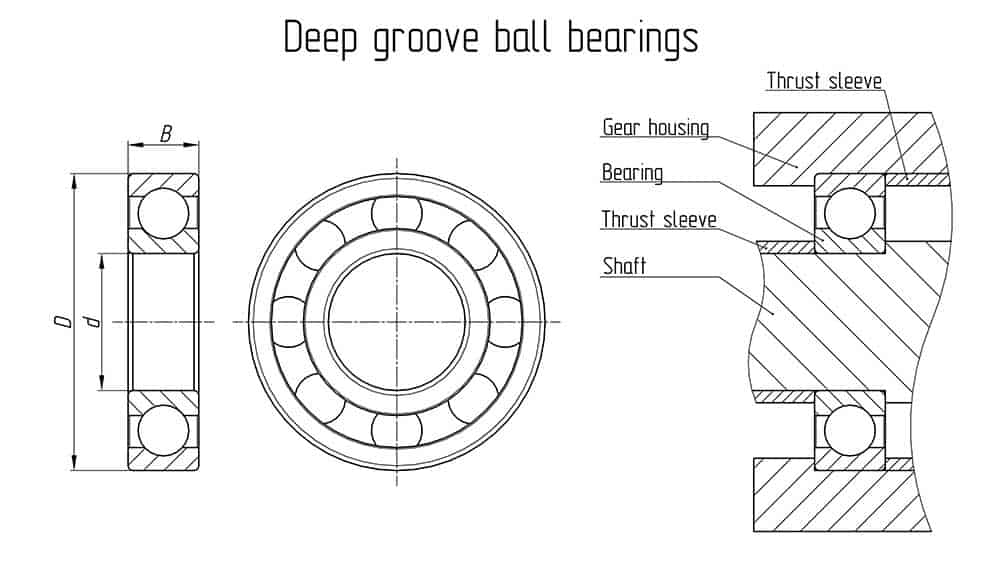

(A schematic drawing with some parts)

Here, you use graphic symbols and lines to represent elements and components. Schematic assembly drawings are common in representing electrical circuits.

Without schematic drawings, understanding circuits and managing complex designs would be difficult. Surprisingly, it’s from the schematics that we develop electronic devices.

Machine Shop Drawings

A machine shop or workshop drawings cover the fabrication and construction process. Surprisingly, they’re available to serve the end user who constantly interacts with the machine.

You’ll note that these drawings originate from contractors, manufacturers, and fabricators. Interestingly, they’ll only avail information that the end user needs.

It usually includes the unit installation, materials in use, and the unit’s structure size. Also, it might include the design and shape of the unit.

Check out below for where to expect machine shop drawings:

- Appliances

- Windows

- Trusses

- Elevators

- Structural steel

- Air handling units

- Millwork

- Cabinetry

- Precast concrete

Importance of Assembly Drawings

(An design engineer drawing)

Generally, assembly drawings are the best way for technical designers and engineers to communicate. Surprisingly, if one engineer prepares an assembly drawing, another engineer from a different location will understand it without any explanation.

Therefore, it becomes possible to produce different machines with accurate and correct assembly drawings.

However, you should have technical knowledge of conventional drafting practices and principles to understand and develop assembly drawings. Without this, you might face misinterpretation and possible litigation.

If assembly drawings weren’t available, you would convey technical ideas in writing or speech rather than in graphical language. This would be difficult to understand and would result in errors.

Interestingly, assembly drawings develop objects like locomotives, automobiles, and aircraft.

What is The Difference Between Assembly and Detail drawing?

An assembly drawing is simply a drawing that displays a machine or part of it with its components. Therefore, it’s a sketch of the machine.

However, a detailed drawing narrows down to explore the specific machine parts in detail. Moreover, it illustrates how the parts connect to form a functional machine.

Surprisingly, a detailed drawing comes after an assembly drawing.

A well-detailed drawing should have the following:

- Shape of parts

- Size of the parts

- Limits of accuracy

- Material

- Number of views

- Grade of finish

- Several parts you need.

FAQ

Is assembly drawing worth it?

Yes! The drawings will help you understand your system and define the different components. Manufacturing, designing, and using the machine could be difficult without the drawings.

What should you include in the assembly drawing?

Generally, coming up with a reliable assembly drawing requires technical expertise. Ensure the drawing has the following:

- Instructions

- Reference numbers

- Specification information

- References to shop or detail drawings

- Lists of components

- Notation

- Dimensions

- Symbols

Are there requirements that an assembly drawing should meet?

Yes! All assembly drawings should meet operational, manufacturing, and maintenance requirements.

Conclusion

All technical experts understand how important assembly drawings are. They not only help you during a product’s manufacturing but also help the end user during application.

Therefore, the drawings will help you understand a complete system and the accompanying component.

Consequently, you’ll find designing, manufacturing, and using machines easily. Surprisingly, only experts can understand and manage assembly drawings.