What Are Printed Circuit Boards Made Of? Printed circuit boards, or PCBs, feature in almost every electronic device. They’re in your phones, household appliances, and even the audio-visual equipment in your car.

But what are printed circuit boards made of? Most manufacturers make PCBs using a combination of non-substrate materials and multiple layers of copper circuitry.

However, different types of PCBs get constructed differently; some printed circuit boards have only one layer of copper circuitry.

There are different types of PCBs, each serving unique functions in their respective applications.

Here’s an article on different PCB components and their functions to help you determine which option is best for your needs.

Table of Contents

- What Is a Circuit Board

- How Do Circuit Boards Work?

- Printed Circuit Board Components

- Printed Circuit Board Substrates

- Printed Circuit Board Layers

- FAQs

- Conclusion

What Is a Circuit Board

In simple terms, a circuit board is a printed board etched with electrical pathways and power points. Therefore, its primary function is connecting electric components. Circuit boards appear in virtually all electronic devices and many industrial machines.

How Do Circuit Boards Work?

PCBs contain different electrical components. Each is vital to the device’s functions. Standard PCBs have their components mounted on a non-conductive board.

Afterward, they’re connected to small pathways called traces. Finally, these traces made of copper allow electricity to flow through the board’s components. Manufacturers place each component in small holes drilled on the surface of the PCB.

Single-sided boards have one layer of conducting material made of copper on one side of the board. The other side has no conducting layer. Instead, it’s used to incorporate other electronic components on the board.

Double-sided PCBs have a conductive copper layer and components on both sides of the board. It lets manufacturers make closer routing traces.

It is because they alternate the placement of components between the top and bottom layers using vias. This often proves helpful in many electronic products.

Moreover, you can connect the circuits on one side of the board to the other through holes drilled onto the board.

Printed Circuit Board Components

The components of PCBs include a variety of electrical and mechanical parts. PCB materials have two purposes. The first is conducting electricity, and the second is providing insulation between conducting layers of copper.

The printed circuit board materials have all the components and transmission lines that enable radio frequency and microwave circuits. Furthermore, these materials mix conductive and non-conductive layers bonded together using heat.

However, the PCB materials used in the manufacturing and assembly processes may vary. It depends on the intended purpose of the board. The client’s needs and budget must also factor into the equation.

Customer needs

There are different PCB materials for each type of PCB. Here’s a list of the most popular types of PCB and the main benefits they provide.

Capacitors

Capacitors carry an electrical charge within the board, releasing it when you need more power in other circuit parts.

They collect opposite charges on a pair of conductive layers separated by an insulating material. Capacitors are usually made of metal plates, and an insulating material called a dielectric.

Diodes

Diodes let the electric current in circuit boards flow in one direction but preventing from going in the opposite direction.

As a result, diodes stop the electric current from flowing incorrectly and damage the board and the device with shorts or power surges. The LED (light-emitting diode) is the most common type of diode.

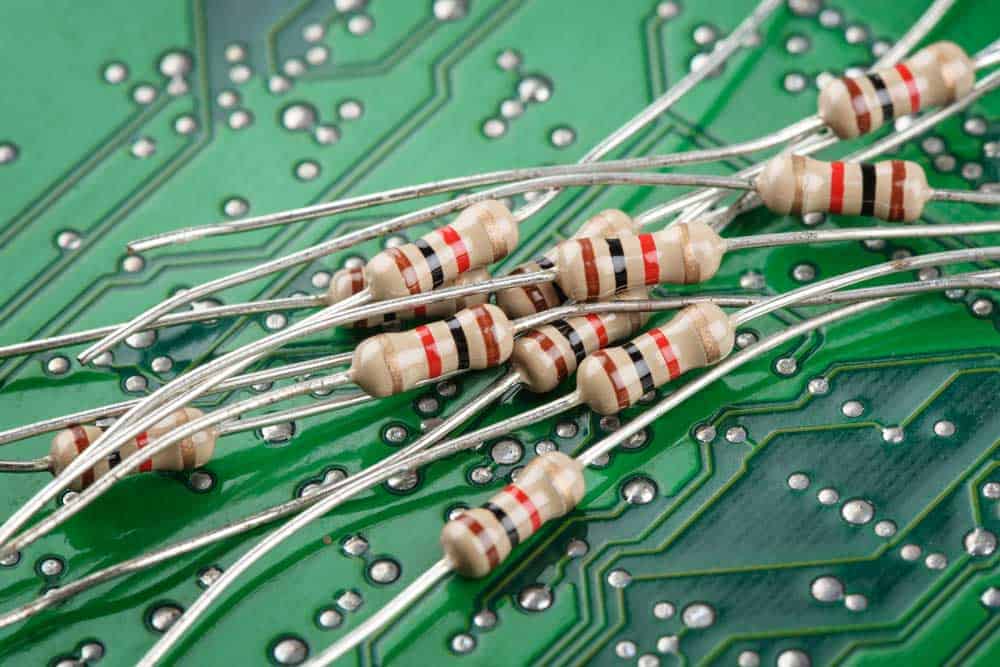

Resistors

A resistor limits or regulates the flow of an electrical current in a circuit. It produces a voltage and dissipates electric power as heat. Common materials used to make resistors include metal alloys, metal oxides, and carbon film.

Closeup resistors on the circuit board

Inductors

Like capacitors, they store electrical energy; unlike capacitors, inductors often block signals within the PCB. One example is blocking interference from another electronic device.

Sensors

Sensors detect changes in the environment the PCB operates. When they detect changes, they generate an electrical signal corresponding to it.

Therefore, the signal gets sent to other components in the circuit board. Sensors can convert a physical element, such as sound, light motion, or air quality, into an electrical current.

Transformers

These components transfer electrical currents between circuits. They do this by decreasing or increasing voltage.

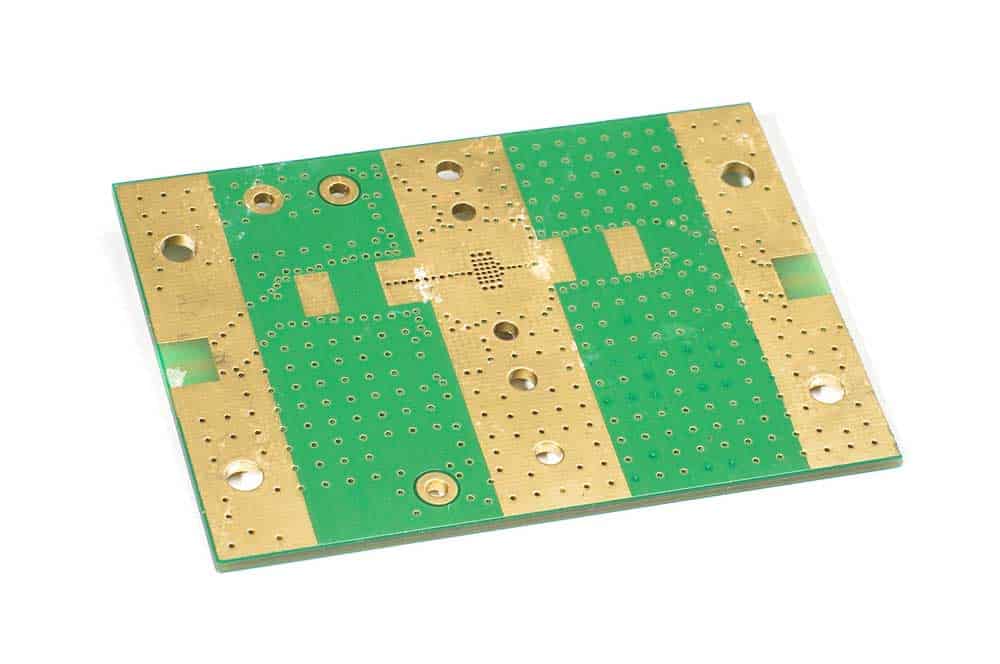

Transistors

Also known as amplifiers, it controls or switches electronic signals inside a circuit board. Again, the most common is the bipolar transistor. However, there exist several different versions.

Prototype high-frequency amplifier

Printed Circuit Board Substrates

The substrate acts as the foundation of the circuit board. It’s the base on which technicians fix components. Because there are different types of PCBs, manufacturers must produce different substrates. Substrates are the most versatile part of circuit boards.

FR-4 Substrate

FR-4 boards make up the majority of PCB boards. It’s lightweight, moisture-resistant, and cheap. They perform well for their cost, making them ideal for consumer electronics.

Flex FCB Substrate

Tech companies would only achieve wearable technology with flex PCB substrates. They can bend because they’re made of soft materials, giving them a variety of applications in wearable devices like smartwatches, hearing aids, and even implants.

Rigid PCB Substrate

Rigid PCB substrates offer the best stability as you can’t bend them and are also shockproof. The Rigid PCBs are cost-effective, using ceramics like aluminum and beryllium oxide.

Flex-Rigid PCB Substrate

These PCB boards offer the best flex and rigid circuit boards, and this versatility comes from their use of both types of materials. Flex-Rigid PCBs feature in aerospace, healthcare, and military applications.

Printed Circuit Board Layers

Substrate Layer

It is the material that gives circuit boards their iconic rigid form. Some PCB substrate layers use epoxy in their construction, but fiberglass is the most preferred material. That’s because fiberglass has greater durability than epoxies.

Silkscreen Layer

The silkscreen layer helps you understand the functionality of different LEDs and pins. In appearance, it’s covered with ink traces in a mix of numbers, letters, and symbols.

These ink traces identify logos and marks, components, test points, warning symbols, and parts of the PCB. The ink used in silkscreens is a non-conductive epoxy that’s highly formulated. Moreover, It comes in shades of black, white, and yellow.

Solder Mask Layer

The solder mask layer goes on top of the copper layer. It’s the iconic flat green segment most people associate with circuit boards. The solder mask layer insulates the copper inside the circuit, preventing it from contacting other elements in the board.

Copper Layer

Most PCBs have a thin layer of copper foil laminated onto the board’s surface using heat.

Single-sided PCBs constitute an underlying layer, a metal layer that it conducts, a protective solder mask, and a silkscreen layer. Moreover, the other side of the board holds different electronic components.

Double-sided PCBs have conductive copper and components on both sides of the board. It allows for the installation of more complex components and circuitry.

The more layers a PCB has, the more copper layers it needs. Again, the more copper layers it has, the more intricate the circuitry is. PCBs with high-power needs tend to have thicker levels of copper.

FAQs

What Material Is PCB Made From?

PCBs have three elements which are copper, fiberglass, and resin. Therefore, these materials work together to meet the desired applications of the device that the circuit board is in.

Are There Any Silicone PCBs?

No. Silicone is too brittle and expensive, making it unsuitable for the mass production of PCBs.

What’s the Difference Between a PCB and a Semiconductor?

A semiconductor PCB works as a conductor and insulator at the same time. The main difference is they’re much larger and broader than other models.

What Materials Insulate PCBs?

Dielectric materials work as insulators in circuit boards. This dielectric material is usually made of porcelain, glass, plastic, and metal oxides.

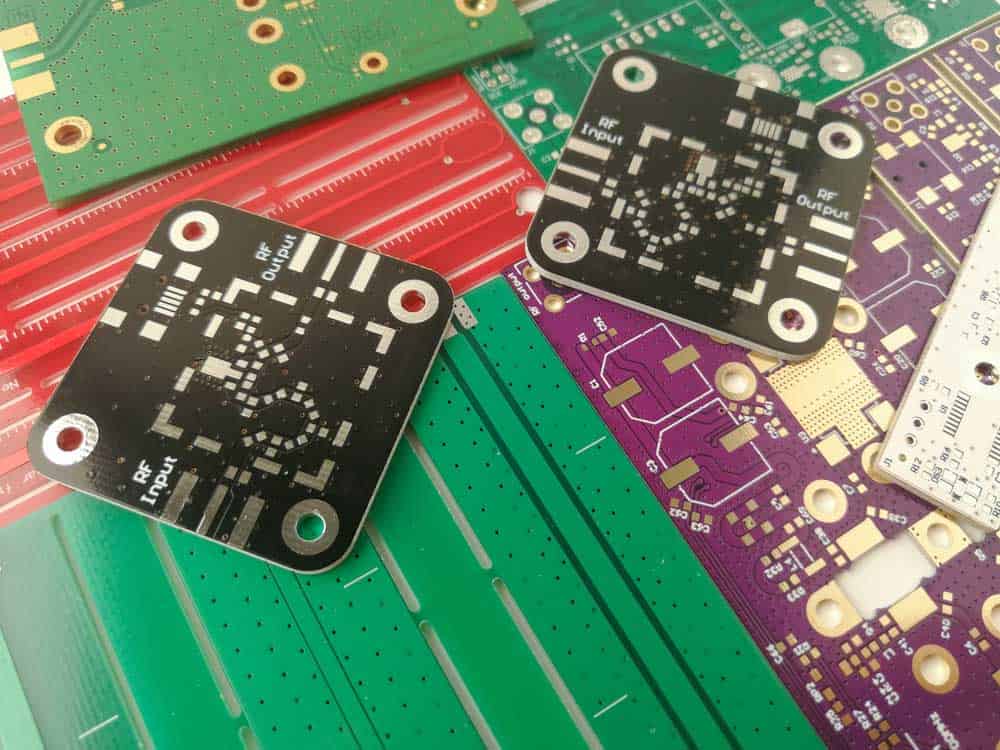

Multi-colored electronic PCBs

Conclusion

Without printed circuit boards, most of our electronic devices wouldn’t function. On a larger scale, many industries would grind to a halt.

Now that you know about their building blocks, you’ll have an easier time repairing or replacing different components. You’ll also know what PCBs to buy for your business or personal needs.

All tech nerds and IT enthusiasts must understand the inner workings of PCBs. Knowing the materials used to make them is the first step.