Regarding Manual vs. Automated PCB Assembly Machines, We usually presume that faster production leads to higher profit margins when considering automation.

Moreover, some may assume that PCB manufacturing giants rely entirely on automated PCB assembly machines. Well, that may be incorrect.

Most PCB assemblers have automated some PCB assembly lines while others assemble manually. You may be wondering what’s the reason they do so. If you are, we’ve got you.

Today we’re highlighting the use of manual vs. automated PCB assembly machines. Moreover, we’re looking at the benefits of each assembly method and why one might suit you better.

Table of Contents

- Manual PCB Assembly

- Automated PCB Assembly

- Benefits of Automating PCB Assembly

- Benefits of Adopting Manual PCB Assembly

- When to Use Manual Assembly Over the Automated Assembly

- FAQs

- The Takeaway

Manual PCB Assembly

Manual PCB assembly is assembling printed circuit boards (PCBs) by hand. The process involves placing and soldering individual components onto a bare PCB.

Afterward, you’ll repeat the placement and soldering process for each component on the PCB until all of them are in place.

Manual PCB assembly can be time-consuming and labor-intensive, especially in large-scale productions. Further, skilled technicians must place components onto the board according to stipulated guidelines.

Consequently, it can be a good option for small-scale production runs. Also, manual PCB assembly is beneficial when the cost of setting up automated assembly is too high.

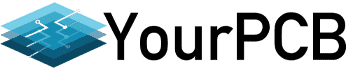

Automated PCB Assembly

(A pick-and-place machine for automated PCB assembly)

Automated PCB assembly is the process of using computer-guided machines and equipment to assemble PCBs. The process doesn’t rely on human labor, making it faster and more efficient for the large-scale assembly of PCBs.

Additionally, the automated assembly has three general steps as follows:

Application of solder paste: Solder paste holds the components in place during assembly.

Component placement: Automated devices like pick-and-place machines position individual components onto the PCB. Moreover, these devices rely on computer-controlled motors to position each component in the right spot.

Reflow soldering: The next step involves the heating of the PCB in a reflow oven. The step melts the solder paste and automatically solders the components to the PCB.

Benefits of Automating PCB Assembly

(Robot assembling a printed circuit board)

Automated assembly relies on computer-controlled machines to place components on the PCB. As such, it is faster and more efficient than manual assembly lines.

However, the high start-up cost makes automated assembly a reserve for large PCB manufacturers.

Here, let’s look at some benefits of automating your PCB assembly.

Low Running Costs and Higher Profits

Automated PCB assembly runs on a circuit board assembly program. These programs control the machines leading to high-quality printed circuit boards.

The result is that it leads to the reduction of mistakes and the potential for delay. Additionally, you can fix any design flaws the system identifies before propagating them to other circuit boards. Ultimately, this results in a considerable reduction in expenses.

Consistency and Accuracy

Automated assembly guarantees the accuracy and consistency of each PCB. Consequently, this lessens the possibility of mistakes or flaws in the final product.

Miniaturization

Small electronic devices, including watches, use miniature printed circuit boards. For these, going with the manual assembly way would be time-consuming and non-profitable.

Luckily, through automation, you can use computer programs to direct the placement of components on the minute boards.

Increased Capacity

Automated assembly can handle a larger volume of PCBs than manual assembly. Therefore, manufacturers can increase their production capacity without hiring additional staff.

Benefits of Adopting Manual PCB Assembly

(Manual assembly of a robotic arm PCB)

Automated PCB assembly has grown in popularity recently owing to its effectiveness and speed. However, its shortcomings encourage PCB manufacturers to adopt manual assembly. Here are the benefits of doing so:

Low Initial Costs

Manual PCB assembly is typically done by hand and with the help of a magnifying device. Generally, we manually assemble PCBs that come in low-volume orders.

For these PCBs, installing an assembly line would be costly. Additionally, manual PCB assembly helps when placing delicate components on the board.

The components include all parts that are delicate enough that you should not assemble them automatically.

Flexibility

The manual PCB assembly allows for greater flexibility in the types of components to use. Moreover, you can customize the placement of those components on the board.

Such a process can be helpful for more complex circuits that require a high level of customization.

Better Accessibility

Manual assembly is more accessible to smaller businesses or hobbyists. That includes those who lack the resources to invest in automated assembly lines for PCB manufacturing.

Additionally, it suits PCB manufacturers who prefer greater control over the assembly process.

More Control of Assembly

The manual PCB assembly provides greater control over the assembly process by allowing for attention to detail. Furthermore, it allows a manufacturer to spot potential issues early during assembly.

Consequently, manual assembly is essential for complex circuits with high-reliability requirements.

Better Clean-Up Process

Sometimes, you may encounter a challenging PCB that’s hard to inspect through automated optical systems. You’ll have to manually inspect such circuit boards to ensure everything is properly positioned.

Moreover, SMT connections and floating items from the reflow process need a manual inspection.

When to Use Manual Assembly Over the Automated Assembly

(Two engineers discussing a PCB)

A PCB assembly service cannot have a one-size-fits-all approach. Therefore, manufacturers must rely on manual and automated techniques to produce the goods. Sometimes, it’s more profitable going with manual assembly. Here are the reasons why:

First, automated assembly requires massive finances to set up. Manual assembly is wise if you are working on a low-volume PCB assembly. You’ll not only save a lot of money in installation costs, but you’ll also work faster that way.

Second, if you’re assembling through-hole components onto a board, it is wiser to go with manual assembly. Other ideal candidates include press-fit connectors and stand-offs.

Third, some manufacturers encourage the manual assembly of components with odd placement. These include components and configurations beyond the capabilities of automated assembly lines.

Fourth, manual assembly is usually a last resort during the automated assembly process.

After finalizing the board, you’ll manually inspect and solder any areas with soldering problems. Furthermore, you’ll have to touch up some SMT connectors for better PCB performance manually.

FAQs

Is automated assembly expensive?

The cost of automated PCB assembly can vary depending on several factors. First is the complexity of the circuit board.

Complex PCBs require specialized equipment to assemble, making the overall production expensive. Second, the level of automation will also determine the cost of production.

Generally, automating production is cheaper in the long run. However, if you’re working on a short-term project, it would be wise to outsource some areas of your production.

While the initial investment in automated assembly equipment can be significant, the cost per unit can be lower in the long run.

The reason is that you’ll increase efficiency and reduce labor costs. Additionally, automated assembly can reduce the risk of errors, which can help prevent costly rework and delays.

Manual vs. Automated PCB Assembly Machines: How long does PCB assembly take?

The time it takes to assemble a PCB from start to finish depends on many factors. First, it depends on the circuit board’s complexity. Complex boards take longer to assemble than simpler boards.

However, this also depends on your level of automation and your custom requirements. Moreover, for a simple through-hole mounting technology PCB, the assembly process may only take a few minutes to complete.

However, the assembly process can take longer for a more complex PCB with hundreds of components and SMT. Sometimes it may take hours or even days to complete a single board.

Manual vs. Automated PCB Assembly Machines: Is a PCB analog or digital?

A PCB isn’t analog or digital. Rather, we use a physical substrate to connect electronic components and devices.

The confusion comes in when considering that components and circuits on the PCB can be analog or digital. Analog circuits process signals that vary continuously, like audio.

On the other hand, digital circuits process discrete signals like data in a computer or digital audio.

The Takeaway

As much as we continue to embrace the growth in automation, we should still appreciate the human effort in the PCB assembly process.

Surprisingly, automated assembly machines have shortcomings you can overcome by taking over some parts of the process.

Additionally, they are expensive to install and maintain. Therefore, you can employ them for large-scale PCB assemblies to increase profits. Otherwise, you’re better off with manual assembly. It is cheaper and doesn’t require much start-up costs.