Can You Repair Circuit Boards? Knowing how to fix PCBs is essential if you work with electronic devices often. The bigger the circuit board, the more money it costs.

You can save time and money if you know how to fix a damaged PCB. All you have to do is understand circuit boards, their components, and the tools required for the job.

But how can you repair circuit boards? It’s a complex process that takes thousands of hours of mastery and in-depth technical knowledge.

You only need specific tools and basic knowledge of how PCBs work. Your willingness to learn and make mistakes will determine how quickly you master circuit board repairs.

This article will outline the factors involved in fixing faulty or damaged circuit boards, including how to diagnose problems, what tools to use, and how to address specific issues.

Table of Contents

- Why Do You Need to Know How to Repair Circuit Board?

- Why Do Circuit Boards Fail

- Can a Circuit Board Be Repaired

- Why Do You Need to Repair a Circuit Board?

- What Are Some of the Tools That You Will Need to Repair Circuit Boards?

- What Steps Should I Follow When Repairing a PCB

- FAQs

- Conclusion:

Why Do You Need to Know How to Repair Circuit Board?

Printed circuit boards may fail or become defective for different reasons, leading to complete or partial electrical failure.

It often happens when circuit boards get mishandled or stored in hostile conditions that cause their components to degrade. In addition, age is a factor leading to circuit board issues.

Sometimes, you can repair PCB damage yourself. However, since it’s such a sensitive and vital piece of technology, you must know how to fix defective circuit boards and diagnose their cause.

Detail of a PCB with many electrical components

Why Do Circuit Boards Fail

Several factors can cause circuit board failure. Here are some of the notable few;

Design Flaws

Sometimes, engineers use shortcuts when designing a circuit board or manufacturing its components. It results in a flawed design and poorly constructed board, which is bound to cause problems later on.

Therefore, poorly designed or built circuit boards frequently develop mechanical and electrical issues.

Electrical engineer repairing electric box

Physical Damage

Physical damage is the most common cause of circuit board failure. If, for example, you drop your keyboard from a great height, it could shake up the internal circuitry, causing electrical or mechanical components to come loose or break entirely.

Faulty Components

After physical damage, faulty components come in at a close second as one of the leading causes of damaged circuit boards. If you haven’t dropped your device and it suddenly stops working, there’s a good chance the printed circuit board has an issue with one or more of its components.

It may be a diode capacitor or a memory chip microprocessor. If the component in question doesn’t work right or is completely inactive, you’ll have to replace it.

In other cases, the trace circuit deteriorates due to age, overheating, or voltage sags, meaning the board is no longer conductive and the components have no access to electrical power.

If you’re lucky, the component may have come loose and needs to be soldered or glued back in place.

Trace Damage

In circuit boards, the traces act as conductive pathways. They can do this because they’re made of metal, usually silver or copper. You can often spot an issue with traces using the naked eye, but it’s not always the case.

If the trace of your circuit board gets damaged due to age, overuse, or physical damage, it will cause conductivity problems.

As a result, the components mounted to the board get affected, and the device doesn’t work correctly. Finally, trace damage may also occur due to overheating, power shorts, surges, and in rare cases, lightning strikes.

Electricity short circuit

Power Failure

A major power failure may affect part or all of the board. Sometimes one of the PCB components gets exposed to higher voltages than normal, such as during power surges. As a result, the components sustain severe heat damage and may even explode.

In other cases, power failures result from a trace failure causing a short somewhere in the circuit. Either way, you can use a power meter to test every component and the board’s general conductivity.

Can a Circuit Board Be Repaired

Is it possible to repair a circuit board? Indeed, you can even do it yourself. However, it is worth noting that your ability to fix a circuit board depends on the type and extent of the damage. You also need specific equipment.

The technician repair the circuit board with a screwdriver

Why Do You Need to Repair a Circuit Board?

Every tech nerd, budding DIY amateur, and engineer must confront a damaged circuit board at some point. You could throw it out and get a new one, but that can get expensive fast, especially if you’ve got a bigger board of more pricy components.

First, if you’ve got the tools and the knowledge to fix the board, then this is a problem you can solve in a few minutes or hours from the comfort of your home or workstation. It’ll save you money and teach you some skills too. Skills that will prove helpful in your career or hobby.

What Are Some of the Tools That You Will Need to Repair Circuit Boards?

You need the right tools for the job to repair a circuit board.

Multimeter

This is the most critical tool for circuit board repairs. A multimeter lets you test different circuit board parts as a diagnostic tool for the tracks and faulty components. Moreover, they measure both voltage and resistance, down to AC and DC voltage.

Therefore, a multimeter and learning to read one are essential. To use a multimeter effectively, you need some experience and practice to understand how circuit boards and their electronic components work.

With a bit of training and practice, you can do it quickly.

Soldering Gun

Soldering guns help join components, like joining copper wires in circuit boards.

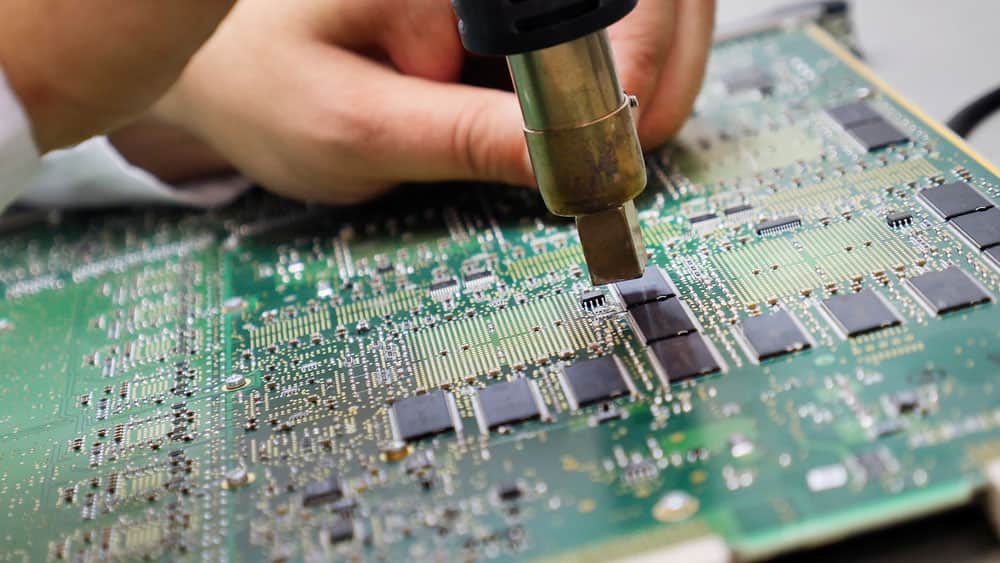

Hot Air Gun

You’ll also need a PCB hot air gun to disassemble and reassemble components on a circuit board.

A technician using a hot air gun to repair a logic board

Copper Foil

Copper foil is a must if you’re working on a multi-layer PCB. The conductive layers of the circuit board trace use copper.

PCB Holder

This tool lets you hold the PCB in place when testing and using the soldering or hot air guns.

What Steps Should I Follow When Repairing a PCB

The steps you take to repair a PCB depend on the damage sustained.

If it’s physical damage, you must melt the circuit board and repair it through disassembly and reassembly. You probably can’t do this as a DIY project unless you have experience with printed circuit board repair.

Most of the time, you’ll have to remodel the board, resolder its components, and lay down fresh conductive traces. However, if it’s your first time, this part is better off left to professionals.

Repairing trace damage or component failure is a more straightforward task. You can scan the damage with a multimeter and resolder the board with new components.

- First, identify the faulty component using a multimeter.

- Remove the faulty pad or component using the soldering gun. Use a hot air gun instead if it’s an SMD (surface-mounted) component.

- Clean the track and remove the solder. Place your copper tape over the track. Restore the PCB through-hole.

- Place the component in the hole(s). Using the soldering gun, weld the joints in place.

- Lastly, trim excess tape and copper foil from the repaired area(s).

FAQs

Can You Repair a Circuit Board?

If a PCB has light damage, repairing it isn’t difficult. However, some electronic PCBs get restricted for repair. In some cases, if the board has extensive damage, you’ll have to get a new one.

How Can I Tell if My Circuit Board Got Damaged?

A visual inspection is a simple way to diagnose circuit board damage. Therefore, you must repair your PCB if you notice any bulges, crushed components, split wires, or burn marks.

What Can Damage a Circuit Board?

Common causes of damage to circuit boards include physical damage, poorly manufactured components or design flaws, and power surges or short circuits.

How Can I Tell a Blown Fuse

A dark metallic smear inside the glass indicates a blown a fuse on a circuit board.

Conclusion:

Printed Circuit Boards (PCBs) can develop issues due to age, mishandling, or poor design.

It makes the ability to diagnose and repair problems with circuit boards quite helpful, whether you’re working in IT as a professional or just an amateur hobbyist who prefers to fix your problems.

Therefore, always give yourself the necessary tools and knowledge to do the job.