Circuit board corrosion, like any system, will deteriorate with time. Most of its components have varying lifespans, and you may need to replace others first.

Generally, PCBs last long, especially if you keep them in good condition. But that’s if you keep your board from elements that encourage corrosion.

In today’s piece, we’re looking at circuit board corrosion, types, and how to clean your board.

Additionally, we’ll delve into the best methods that you can use to prevent your board from corroding. Let’s get rolling.

Table of Contents

- What’s Circuit Board Corrosion?

- Types of Circuit Board Corrosion

- How To Clean A Corroded Circuit Board

- How To Prevent Corrosion on Circuit Board

- FAQ

- Final Remarks

What’s Circuit Board Corrosion?

(A corroded circuit board)

Circuit board corrosion is when a PCB deteriorates due to chemical reactions on its surface.

The chemical reactions occur when you expose the PCB to environmental factors such as moisture and chemicals.

The result is that some components and metal traces will weaken and become nonfunctional. Additionally, we have visible and nonvisible corrosion.

The former occurs on the board’s surface, which you can notice from the discoloration.

On the other hand, nonvisible discoloration happens inside the board’s layers. It affects the board’s electrical properties without any signs of physical deterioration.

Types of Circuit Board Corrosion

(A damaged circuit board)

Circuit board corrosion is dangerous as it lowers the board’s structural integrity.

Additionally, it damages copper traces that are important for your board to conduct electricity.

Consequently, your device malfunctions necessitating a replacement of the board.

Here are some types of corrosion that commonly happen in circuit boards.

Surface Corrosion

The most common type of corrosion occurs on a circuit board’s surface.

If you inspect one and spot discoloration, pitting, or flaking on the surface, it may have surface corrosion.

Moreover, it results from exposure to moisture, salt, or other environmental factors.

Crevice Corrosion

Crevice corrosion leads to localized damage around components and undercoatings.

Other corrosions that fall under this bracket include pitting and filiform corrosions. The three corrosions damage a small area that weakens the circuit board’s structure.

Galvanic Corrosion

Galvanic corrosion occurs at the point of contact between two or more metals and an electrolyte. As a result, one metal corrodes faster than the other, causing cracking or delamination of the board.

Chemical Corrosion

This corrosion happens when your PCB touches corrosive chemicals like acids and bases. The result will rapidly deteriorate your circuit board’s circuitry and components.

Atmospheric Corrosion

It is a corrosion that mostly happens in circuit boards we use in an industrial setup. It happens when you expose a circuit board to pollutants like nitrogen oxides and moisture.

Additionally, most copper components suffer from atmospheric corrosion. While copper will continue to have mechanical qualities after corrosion, it will lose its conductivity.

Creation of Electrolytic Dendrites

Electrolytic dendrite growth takes place when there is an ionic impurity in moisture. Consequently, metal slivers grow between nearby copper traces that have different voltages.

Ultimately, the slivers will come into contact short-circuiting your printed circuit board.

How To Clean A Corroded Circuit Board

(Using a toothbrush and water to remove corrosion from a computer motherboard)

Circuit boards can accumulate a lot of unwanted materials that may affect their performance.

Materials such as dirt and dust in large quantities may cause overheating or even failure of your board.

Thus, we recommend adopting the following techniques to clean your board.

Using Compressed Air

Using compressed air is a standard method of cleaning PCBs. All you have to do is release short bursts of air onto the circuit board’s surface, and it will blow away all the dust.

However, be careful not to use too much pressure as it may damage weak circuit board components.

Use Distilled Water

Water is a good conductor of electricity. Hence, most people are wary of using distilled water to clean their circuit boards. FYI, distilled water is a poor conductor of electricity and won’t short-circuit your device.

Use Baking Soda

You can use baking soda to clean corrosion from your printed circuit boards. And the good thing is that baking soda is readily available, and you may have it right in your kitchen.

It is mildly abrasive, making it ideal for removing corrosion from board surfaces.

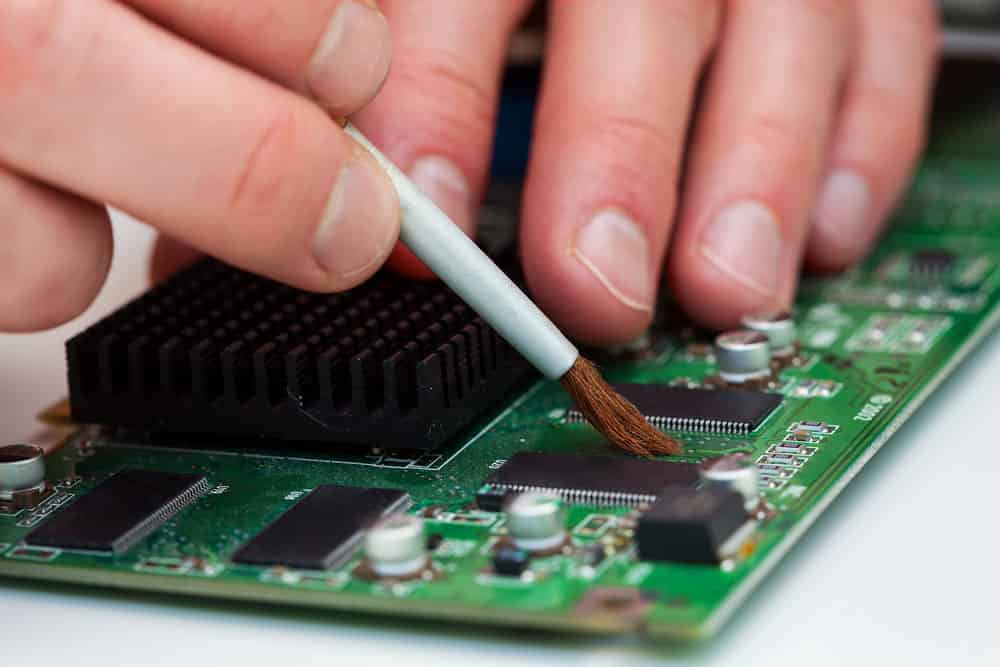

Use a Brush

(Using a brush to clean a PCB)

A brush can be a valuable tool for cleaning your circuit boards. The reason is that it can reach all of the tiny components and holes.

However, you must make sure the one you select has soft bristles.

Scale is important since you must fit into even the most minor locations. Moreover, most people prefer to use a paintbrush or a toothbrush as they are strong and delicate.

But remember to keep lint-free microfiber wipes on hand to wipe down and dry your circuit board after cleaning it.

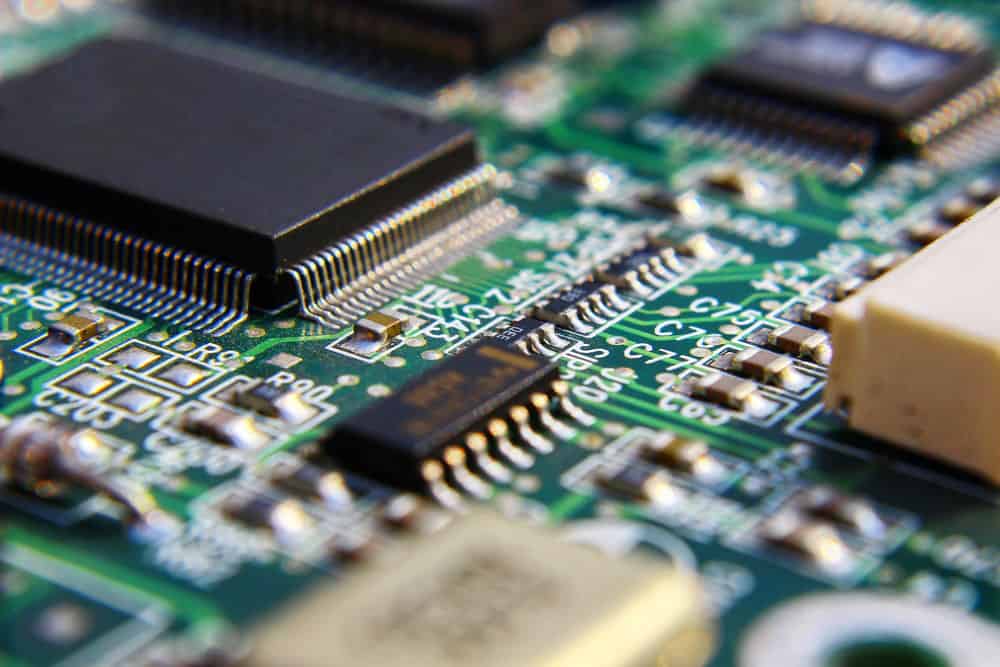

How To Prevent Corrosion on Circuit Board

(A circuit board that’s in good condition)

Corrosion risk varies significantly across different metals. Moreover, all metals eventually corrode, but noble metals corrode far more slowly than copper and other base metals.

One would expect PCB manufacturers to opt to go with noble metals. However, that is not the case, as they’re costlier and not viable for certain projects.

As a result, PCB engineers prefer using copper and adopting ways of preventing corrosion.

First, keeping your circuit board from areas with a high moisture content is advisable. From science, we know that certain metals corrode when they come into contact with moisture.

To prevent them from rusting, store their PCBs in a dry environment. Second, a conformal coating can prevent contaminants from contacting the board.

Third, you can opt for high-quality components with higher corrosion resistance. Therefore, these will prevent corrosion from spreading to other board areas.

Fourth, PCB manufacturers use corrosion-resistant materials like palladium to extend their board’s lifespan. If you don’t find palladium, you can opt for gold plating.

Fifth, you can conduct regular inspections of your board to detect corrosion. Afterward, take early preventive measures if you can spot areas starting to rust.

However, regular maintenance can prove costly and not viable for applications with many PCBs.

FAQ

Does corrosion damage the circuit board?

Yes, corrosion damages your circuit board. Generally, we know that corrosion wears out parts of a metal or any substance, causing it to fail.

Similarly, corrosion introduces impurities that may lower the effectiveness of a certain system. More specifically, it damages the structural integrity of your circuit board.

For instance, most circuit boards are thin, and each part plays an important role in the setup.

Some components may fail to function when corrosion occurs, leading to your device failing.

Additionally, it may cause short-circuiting and other problems that ruin the working of your circuit boards.

How do you identify a Corroded PCB?

Have you ever seen a circuit board with components falling over or even a change of color?

Chances are that your circuit board is corroded, and you might need to inspect it further.

First, look for pitting or discoloration traces on the board’s surface. If you can see any, your board is likely to be corrupted.

Second, inspect all of your board’s components for any damages. You can try to do this by moving the component slightly.

It is weak from corrosion if it is brittle or tends to sway abnormally.

Thirdly, use a multimeter to check the conductivity and resistance of your circuit board. Any abnormalities like higher resistance show that your board has corrosion.

Can you fix a corroded circuit board?

The answer to the question above depends on the extent of the corrosion. Sometimes, detecting corrosion at its early stages will save you some money as you can detect and repair it in time.

However, some boards erode to the point of losing their electrical and structural integrity. If yours is at this point, it is best to discard it as it may be of little use.

Moreover, attempting to fix it may cost you a lot of money to the point that buying a new one is cheaper.

Final Remarks

In today’s article, we’ve reviewed most information regarding circuit board corrosion. As we’ve seen, circuit boards are made from durable materials, and their corrosion results from other factors.

These factors are preventive, and you can prolong your board’s lifespan with the right measures.

Additionally, we recommend using high-quality materials when manufacturing your board.

Doing so will save you a lot of resources that you may spend on repairs and general maintenance.